Rotech Pumps & Systems is a leading manufacturer & Supplier of various types of pumps, mechanical seals, and valves. We engage ourselves in designing and developing comprehensive and effective pumping solutions. We achieve this through research & development and thorough testing. One such range of efficient pumping products is vertical centrifugal pumps. The series includes vertical inline pumps and vertical multistage pumps.

This article lets you explore more about the series of vertical centrifugal pumps from Rotech. Know more about the functions, applications, and advantages of vertical inline pumps and vertical multistage pumps. Vertical centrifugal pumps are innovative and are significantly different than horizontal centrifugal pumps. Determine the difference between horizontal and vertical centrifugal pumps.

The Key Difference & Functionality

A vertical centrifugal pump has a vertically oriented shaft. The design of the shaft is radial split and overhang. Before choosing between the two types of pumps, you need to consider the factors such as maintenance, installation space, functionalities, and applications. Vertical centrifugal pumps are apt when you have a limited surface area. They are perfect for liquids with high temperatures and pressure and have a wide range of applications.

The vertical centrifugal pumps get coupled with electric motors. The impeller gets connected over the shaft with the electric motor that rotates at a predefined speed and produces a centrifugal effect. These vertical centrifugal pumps are operated by a direct-drive motor and have high-performance data regarding flow rate. The robust construction of these pumps avoids the use of internal mechanical seals. The mechanical seals are often interchangeable.

The open impeller allows continuous pumping of even dirty liquids or media containing small solids. The construction and design of these pumps make them reliable for guaranteed continuous operation and ensure longevity.

Advantages

- Vertical centrifugal pumps have high chemical and thermal resistance because they are robust in construction.

- They are suitable for continuous operations.

- They are easy to install even without disturbing the piping.

- They are frequently available and interchangeable with inexpensive spare parts.

- They are reliable and have higher applicability even with extremely dirty liquids or media containing small solids.

They are quick and easy to maintain.

Vertical Pumps from Rotech

RVMS Series Vertical Multistage Pumps

RVMS is a vertical non-self-priming multistage centrifugal pump driven by a standard electric motor. The motor output shaft directly connects with the pump shaft through a coupling. The pressure-resistant cylinder and flow passage components get fixed between the pump head and inlet & outlet section with tie-bar bolts. The inlet and outlet are at the pump bottom at the same plane.

RVMS pumps are stainless steel vertical multistage pumps available in wide ranges and sizes. Pumps get supplied with 150# and 300# ANSI flanges.

Rotech Vertical Multistage Pumps are suitable for pumping slightly corrosive liquids. They get designed with standard cast iron bases and stainless steel flange connections.

Applications

- Water supply: water filtration, transporting liquid to water works, pressure boosting of the main line, pressure boosting in high-rise buildings.

- Industrial: pressure boosting, process flow water system, cleaning system, high-pressure washing system, fire-fighting system, industrial liquid transfer, HVAC, boiler feed water application, condensing system.

- Water treatment: ultrafiltration system, reverse osmosis system, distillation system, separator, swimming pool.

Irrigation: farmland irrigation, spray irrigation, dripping irrigation.

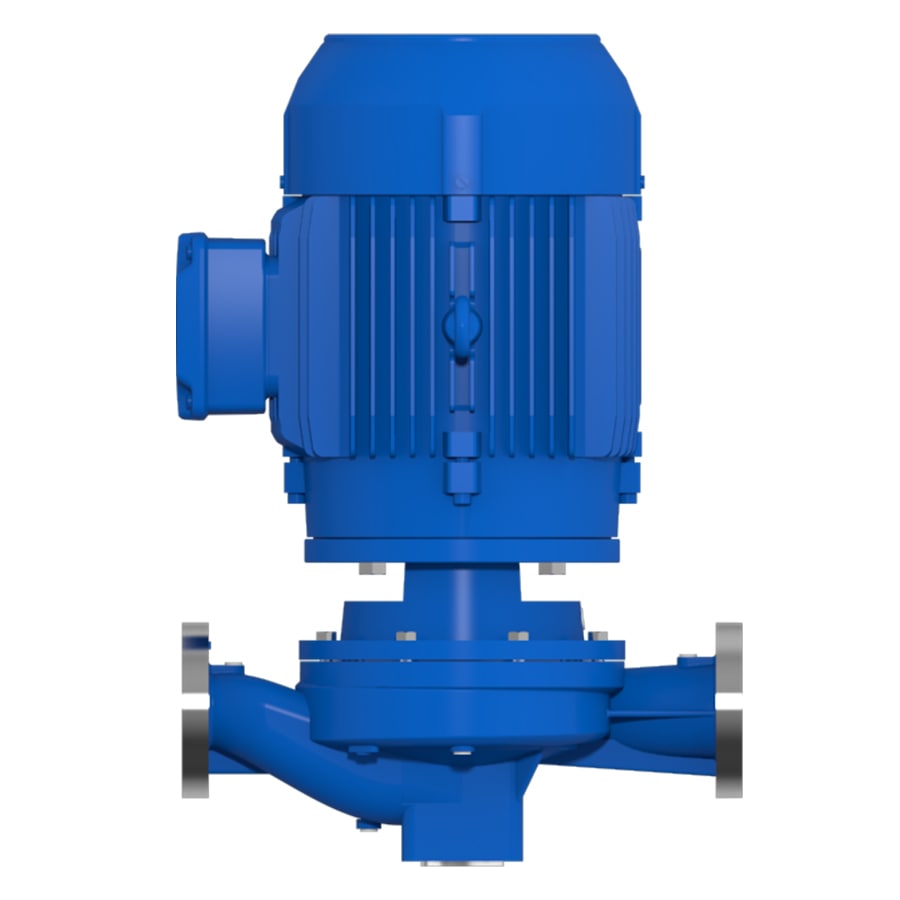

RVI80 Series Vertical Inline Pumps

Rotech RVI80 Vertical Inline Pumps are close-coupled pumps designed for easy installation and can get mounted to a pipeline. The Suction and Discharge connections are on the same center line in the opposite direction at 180º apart.

These types of pumps are easy to install even without disturbing the piping. These are close-coupled pumps and don’t require extra space, rigid base, or alignment. The impeller gets mounted on the motor shaft, and the pump adaptors are interchangeable with the same series of pump sizes. These pumps get supplied with mechanical seals and flush lines to cool seal faces.

Applications

- Pressure boosting systems

- Apartment buildings

- Industrial process systems

- General circulating water services

- Heating and Air conditioning

At Rotech, we are committed to pumping solutions, that’s why we call ourselves the pump people. We have an experienced team of engineers and an extensive, in-house testing facility for effective pumping solutions.

Rotech can help you select pumps and systems based on your application needs. You can consult with us to know more about our vertical pumps – vertical inline pumps and vertical multistage pumps. Rotech strives to provide the best quality products at competitive prices with Minimum lead time. We offer quick turnaround on inquiries and support with a team ready to serve you.

Recent Posts

A Comprehensive Guide to Types of Water Pumps and Their Applications

Introduction Water pumps are indispensable

The Complete Guide to Water Pumps: Types, Uses, and Maintenance

Water is life, and the

Comprehensive Guide to Split Case Pumps

Split case pumps are a