Centrifugal pumps are an essential part of many industrial and commercial applications, including water supply, irrigation, and chemical processing. However, these pumps are prone to a phenomenon known as cavitation, which can cause severe damage to the pump and decrease its efficiency. In this article, we will discuss how to prevent cavitation in centrifugal pumps and provide insights on factors that affect cavitation, symptoms of cavitation, tools and techniques for cavitation detection, case studies, and advancements in cavitation prevention.

Understanding Cavitation

Centrifugal pumps are an essential part of many industrial and commercial applications, including water supply, irrigation, and chemical processing. However, these pumps are prone to a phenomenon known as cavitation, which can cause severe damage to the pump and decrease its efficiency. In this article, we will discuss how to prevent cavitation in centrifugal pumps and provide insights on factors that affect cavitation, symptoms of cavitation, tools and techniques for cavitation detection, case studies, and advancements in cavitation prevention.

Several factors contribute to cavitation, including pump design, operating conditions, and liquid properties. Pump design factors that affect cavitation include impeller diameter, blade angle, and the number of blades. Operating conditions that contribute to cavitation include high flow rates, low suction pressure, and high temperatures. Finally, liquid properties such as viscosity, density, and vapor pressure can also impact cavitation.

Symptoms of Cavitation in Centrifugal Pumps

There are several symptoms of cavitation in centrifugal pumps that you should look out for. These include:

Noise: Cavitation often produces a distinct noise that can be heard coming from the pump. This noise is typically described as a rattling or clicking sound and is caused by the collapse of the vapor bubbles.

Vibration: As the vapor bubbles collapse, they can cause vibration in the pump. This vibration can be felt through the pump housing or in the piping connected to the pump.

Reduced flow: Cavitation can reduce the flow of liquid through the pump. This is because the formation and collapse of the vapor bubbles can disrupt the smooth flow of liquid.

Reduced pressure: Cavitation can also reduce the pressure of the liquid being pumped. This is because the vapor bubbles take up space in the pump and can reduce the amount of liquid that can be moved through it.

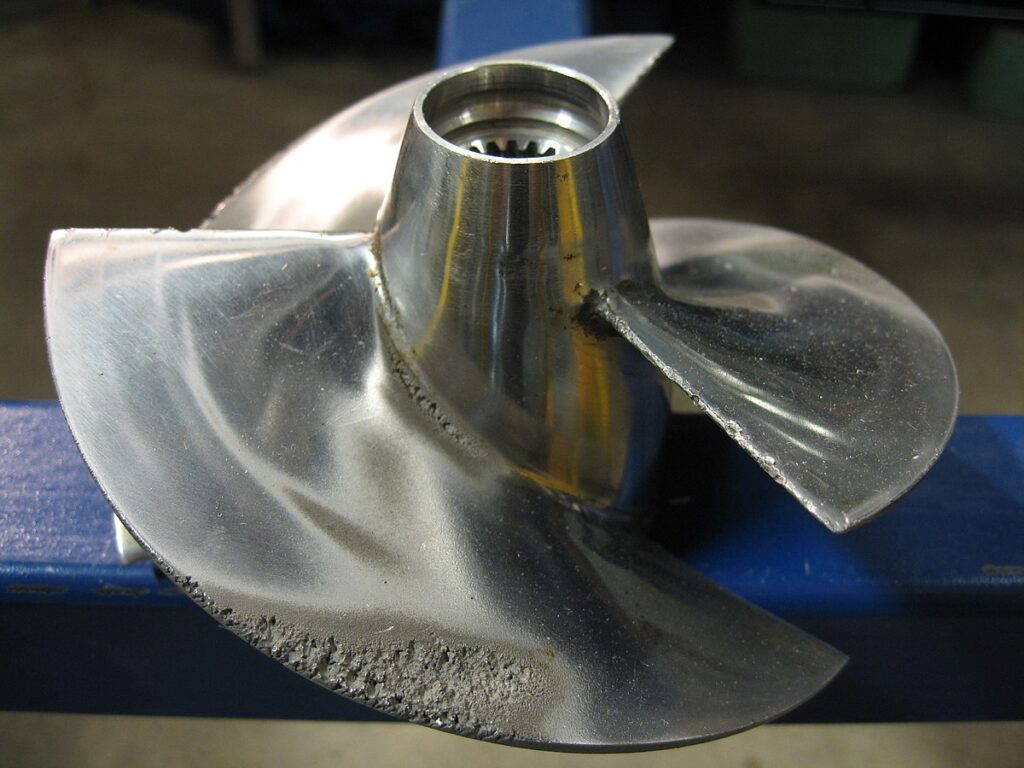

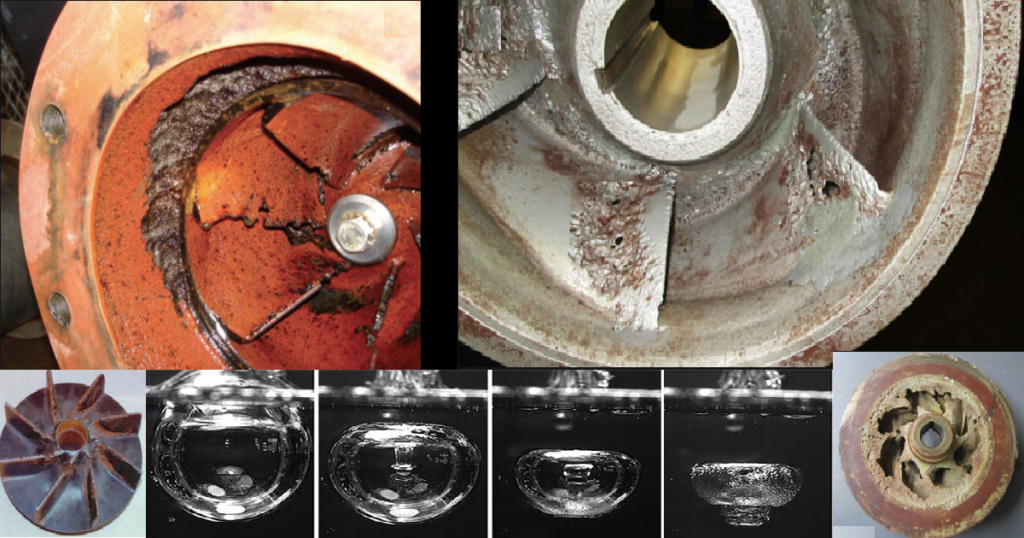

Damage to pump components: Over time, cavitation can cause damage to the impeller, pump housing, and other components of the pump. This is because the collapse of the vapor bubbles creates small shock waves that can cause erosion or pitting of the metal surfaces.

Overheating: Cavitation can also cause the pump to overheat, as the energy of the collapsing bubbles is converted into heat. This can lead to damage to the pump’s seals, bearings, and other components, and it can cause the pump to fail prematurely.

If you notice any of these symptoms in your centrifugal pump, it is important to take action to address the issue. This may involve adjusting the pump speed, increasing the suction pressure, or replacing damaged components. Failure to address cavitation can lead to significant damage to the pump and can result in costly repairs or downtime.

How to prevent Centrifugal Pumps cavitation?

Here are some tips on how to prevent pump cavitation:

Ensure proper suction conditions

The suction side of the pump is where cavitation is most likely to occur. Thus, it is essential to ensure that the suction line is correctly installed, and the suction conditions are optimal. This includes maintaining the proper inlet pressure, ensuring the suction line is straight, and sizing the suction line appropriately. Additionally, ensure that the suction strainer is clean and free of debris to prevent blockages.

Optimize impeller design

The impeller is a critical component of the centrifugal pump that can affect cavitation. The design of the impeller should be optimized to ensure that it produces uniform flow without any turbulence. The impeller should also be correctly sized and have an adequate number of vanes to prevent excessive pressure drops and cavitation.

Control fluid temperature

The fluid temperature can also affect cavitation in centrifugal pumps. When the fluid temperature is too high, it can cause the vapor pressure to decrease, leading to cavitation. On the other hand, when the fluid temperature is too low, it can cause the viscosity to increase, leading to a reduced flow rate and potential cavitation. It is recommended to keep the fluid temperature within the manufacturer’s recommended range.

Use a NPSH margin

The net positive suction head (NPSH) is a critical parameter in preventing cavitation in centrifugal pumps. The NPSH margin is the difference between the available NPSH and the required NPSH. It is essential to maintain an adequate NPSH margin to prevent cavitation. To achieve this, ensure that the suction side of the pump is properly designed, and the fluid velocity is within the recommended range.

Check for leaks

Leaks in the suction line or pump casing can cause air to enter the pump, leading to cavitation. It is essential to check for leaks regularly and repair any detected leaks immediately.

Use appropriate materials

The choice of materials used to construct the centrifugal pump can also affect cavitation. Some materials are more resistant to cavitation than others. Therefore, it is important to choose the appropriate material for the pump casing, impeller, and other components. Materials such as stainless steel or hardened steel can improve the pump’s resistance to cavitation.

Regular maintenance

Regular maintenance of the pump is essential to prevent cavitation. This includes checking the pump’s impeller and other components for damage or wear, ensuring that the pump is properly lubricated, and checking the alignment of the pump and motor.

How to prevent Centrifugal Pumps cavitation?

Cavitation can be detected using several tools and techniques, including ultrasonic inspection, vibration analysis, and acoustic emissions testing.

We will explore some of the tools and techniques used for centrifugal pump cavitation detection.

Visual inspection: A simple but effective technique for detecting cavitation is a visual inspection. Cavitation can cause visible damage to the impeller, such as erosion, pitting, or cracking. By regularly inspecting the pump’s impeller and other components, operators can identify early signs of cavitation and take corrective action before it leads to more significant damage.

Vibration analysis: Cavitation can also cause vibration in the pump, which can be measured and analyzed to detect cavitation. Vibration sensors can be placed on the pump to detect changes in vibration levels and frequencies, which can be indicators of cavitation. By monitoring vibration levels regularly, operators can detect cavitation early on and take action to prevent damage.

Acoustic analysis: Acoustic analysis is another technique used for detecting cavitation in centrifugal pumps. By placing microphones near the pump, operators can detect the noise generated by cavitation bubbles collapsing. The frequency of the noise can be analyzed to determine the severity of cavitation, with higher frequencies indicating more severe cavitation.

Pressure sensors: Pressure sensors can be used to detect cavitation by monitoring the pressure at various points in the pump. If the pressure at the pump’s inlet drops below the fluid’s vapor pressure, it can indicate the onset of cavitation. By monitoring the pressure regularly, operators can detect cavitation early on and take corrective action to prevent damage.

Temperature sensors: Temperature sensors can also be used for cavitation detection. As cavitation bubbles collapse, they release energy in the form of heat, which can be detected by temperature sensors placed near the pump. By monitoring the temperature regularly, operators can detect cavitation and take corrective action before it leads to more significant damage.

Flow Visualization: Flow visualization is a technique that can be used to detect cavitation. It involves injecting a tracer into the fluid and using a high-speed camera to observe the flow patterns. Cavitation can cause the flow patterns to change, which can be observed and analyzed.

Thermal Imaging: Thermal imaging can also be used to detect cavitation. When cavitation occurs, the temperature of the pump components can increase due to the energy released by the collapsing vapor bubbles. Thermal imaging can detect these temperature changes and indicate the presence of cavitation.

Frequently Asked Questions about Centrifugal Pumps cavitation

What are the different types of cavitation?

There are three types of cavitation: suction, discharge, and internal.

How does cavitation affect pump performance?

Cavitation reduces the pump’s efficiency, decreases flow rate and pressure, and causes damage to the pump’s components.

What are the common causes of cavitation in centrifugal pumps?

Common causes of cavitation in centrifugal pumps include high flow rates, low suction pressure, high temperatures, and improper liquid properties.

How can cavitation be detected in centrifugal pumps?

Cavitation can be detected using ultrasonic inspection, vibration analysis, and acoustic emissions testing.

What are the best practices for preventing cavitation in centrifugal pumps?

Best practices for preventing cavitation in centrifugal pumps include optimizing pump design, modifying operating conditions, using proper liquid properties, and ensuring regular maintenance and prompt repairs.

Conclusion

Cavitation is a serious problem in centrifugal pumps that can cause damage and decrease the pump’s efficiency. Understanding the factors that contribute to cavitation, recognizing the symptoms, and using prevention methods can help prevent cavitation and prolong the pump’s lifespan. By optimizing pump design, modifying operating conditions, using proper liquid properties, and performing regular maintenance, industries can avoid costly repairs and improve pump performance. Lastly, advancements in pump design and technologies, such as smart monitoring systems and Computational Fluid Dynamics simulations, provide opportunities for further improvements in cavitation prevention.

Recent Posts

A Comprehensive Guide to Types of Water Pumps and Their Applications

Introduction Water pumps are indispensable

The Complete Guide to Water Pumps: Types, Uses, and Maintenance

Water is life, and the

Comprehensive Guide to Split Case Pumps

Split case pumps are a